E+S SINGLE SLIDE RAIL LINEAR SHORING.

Linear shoring is suitable for casting concrete in-situ place and can be flexibly adapted to any construction project. The ground outside the trench remains largely unaffected, and buildings and traffic flow are not impaired – a level of performance that was long-considered unattainable.

On linear shoring, rigid carriages cars that are height-adjusted to match the increasing depth keep the beams and shoring panels at the same distance apart at all times; the trench width remains unchanged at all stages of the project. The width of the rigid frame is adapted with spreaders to the desired trench width. The carriage maintains precise right angles – everything stays linearly aligned, always at the same distance from the opposite side. This ensures more efficient, faster, better-quality, and noticeably more cost-effective operations, with a major advantage of the system being derived from the design of the beam. For only on the linear shoring system is it possible to pivot in the shoring panels from the side.

BASIC DATA

- Module length: 2.13 m – 6.38 m

- Length slide rail: 4.13 m

- Panel height: 1.32 m / 2.32 m

- Pipe culvert height: variable

- Trench width: variable

ADVANTAGES

- Cost-effective shoring

- No adverse impact on building development or traffic

- Suitable for in-situ concrete

E+S SINGLE SLIDE RAIL INNER-CITY LINEAR SHORING.

In urban areas, trench sections crossed by numerous pipes and cables are commonplace. Using large-area shoring systems is then out of the question. The solution is inner-city linear shoring that combines the piling frame element for guiding sheet piles with the components of the linear shoring system.

By using piling frame elements, linear shoring with single or double slide-rails provides a solution even in those areas where gas or water mains or other service pipes cross the trench. The shoring modules and the piles themselves are lowered largely low-vibration – an important precondition for digging work in towns which usually involves traffic routes and building structures close to the trench.

BASIC DATA

- Module length: 2.84 m / 4.38 m

- Length slide rail: 4.13 m

- Height sheet pile element: 1.00 m

- Length sheet piles (KD VI/8): variable

ADVANTAGES

- Cost-effective shoring wherever transverse electrical lines and house connections exist

- No vibrational or impact forces

E+S SINGLE SLIDE RAIL CORNER SHORING.

Corner rail shoring is a special shoring solution, suitable among other things for work on manholes. When used as manhole shoring, it usually consists of four slide-rail panels and four corner rail beams.

It does not require special bracing systems, and all forces are retained by the shoring panels. With suitable beams, Corner rail shoring can take the form of single-rail or overlapping shoring. Since the panels of various lengths are used in pairs, rectangular pits of different sizes can be constructed.

BASIC DATA

- Module length: 2.13 m – 6.38 m

- Length slide rail: 2.30 m / 4.13 m

- Panel height: 1.32 m / 2.32 m

- Shoring width: 1.75 m – 6.00 m

ADVANTAGES

- Economical shoring solution, e.g. for shaft structures

- Right-angled excavations feasible in a wide range of sizes

E+S SINGLE SLIDE RAIL LINEAR SHORING - X-RAIL.

The cross rail, which is available in a beam length of 4.13 m, allows the shoring to be routed around the corner. As a further development of the corner rail, it ensures maximum flexibility in the excavation pit: feed lines to shafts and collectors, branches and expansion stations for district heating lines can be realized more easily and economically. In the course of soil replacement measures, the area to be worked can simply be divided into quadrants and successively worked through. The shoring panels can be raised in the cross rail in accordance with the structural specifications - this ensures adequate pipe clearance heights when laying pipes and carrying out other work on the trench bottom.

SPECIFICATIONS

- Module length: 2.13 m - 6.38 m

- Cross rail length: 4.13 m

- slab height: 1.32 m / 2.32 m

- Shoring width: 1.75 m - 6.00 m

ADVANTAGES

- Slab guidance at 90° angle

- Ideal for soil replacement and excavation of single shafts

reference projects

Trench Shoring - Linear Shoring

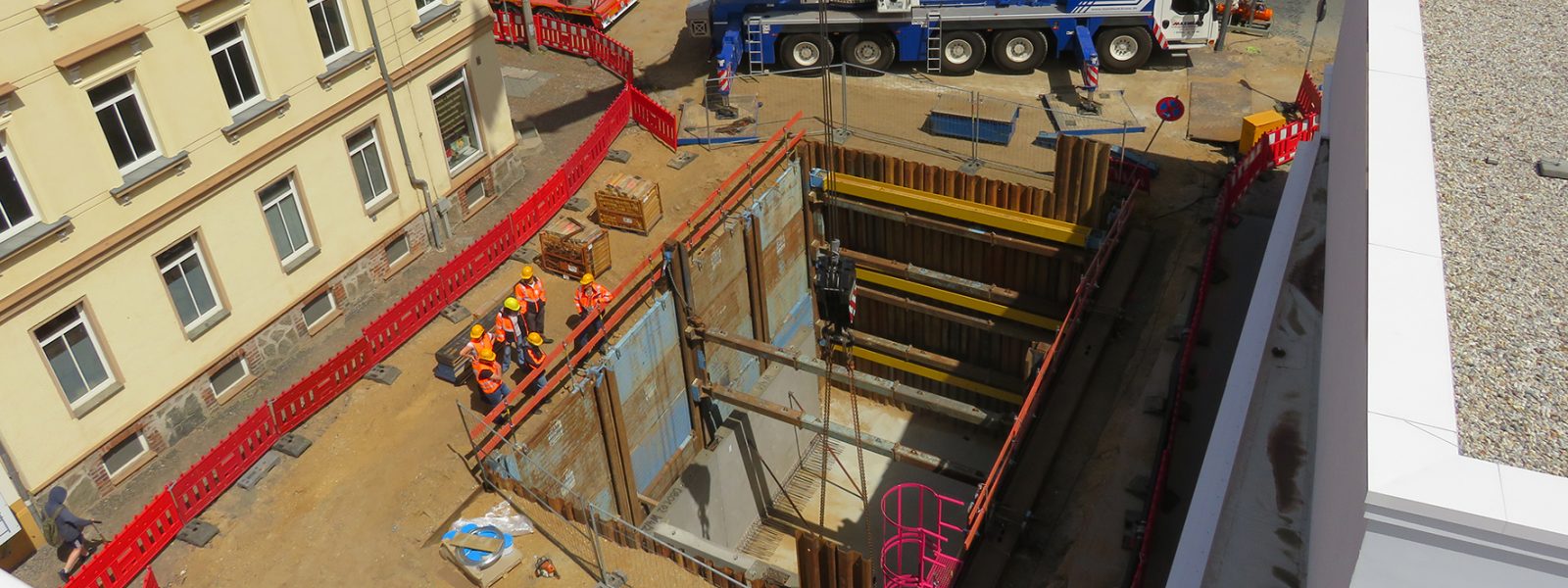

NEUBAU SAMMLER - LINEAR SHORING ENSURES LARGE AND SAFE WORKING SPACE

Read more