MÜLLER EXCAVATOR-MOUNTED VIBRATORY HAMMERS HFB-SERIES.

- MÜLLER: RUNNING STEADY - ROBUST AND RELIABLE

- MINIMUM OVERALL HEIGHT - MAXIMUM PILE LENGTH

- MODULAR SYSTEM - ADAPTABLE TO YOUR REQUIREMENTS

You snooze, you lose!“ is a general saying that we believe in when it comes to the development of our products. That is why our established series MS-4/6/7/9 HFB has recently been subject to a major redesign. We have repositioned and reinforced several machine components in order to make our excavator-mounted vibratory hammers even more robust. Doubling the gear oil has resulted in a longer operating time, all while maintaining our highest MÜLLER performance standard. All machines can be customized to your particular requirements through a modular system containing: 360° rotator, excavator arm extension, various quick coupling systems, drain oil pressure protection, gearbox oil cooling, transportation or equipment stands and an operating hours counter.

KEYDATA

- For use in moderatly heavy and heavy grounds

- Control block with safety circuit

- Easy setup and operation by using the excavator hydraulics

- No intervention in the excavator control necessary

- Clamping device can be mounted 90° rotated

PRODUCT INNOVATIONS

- Modular system

- Gearbox oil has been doubled

- Reinforcement of hydraulic motor cover

- Repositioning of control block outside the danger zone

- Quick and easy monitoring of the oil level through the installation of oil level gauges on each side of the machine

- Compact design: work with longer piles

- Crane-suspended operation possible

MÜLLER EXCAVATOR-MOUNTED VIBRATORY HAMMERS HFB S-SERIES.

Our swivelling excavator-mounted vibratory hammers with fixed eccentric moment are uncomplicated to operate and robust in use. In addition, they allow the pile to be picked up and deposited directly with the clamping device.

HFB S-SERIES.

APPLICATIONS

- Sheet pile driving

ADVANTAGES

- Direct pick-up and set-down

- Extremely low height allows driving of long piles

- Easy setup through excavator hydraulics

- Control block with safety circuit

- Manual or automatic exciter cell interlocks

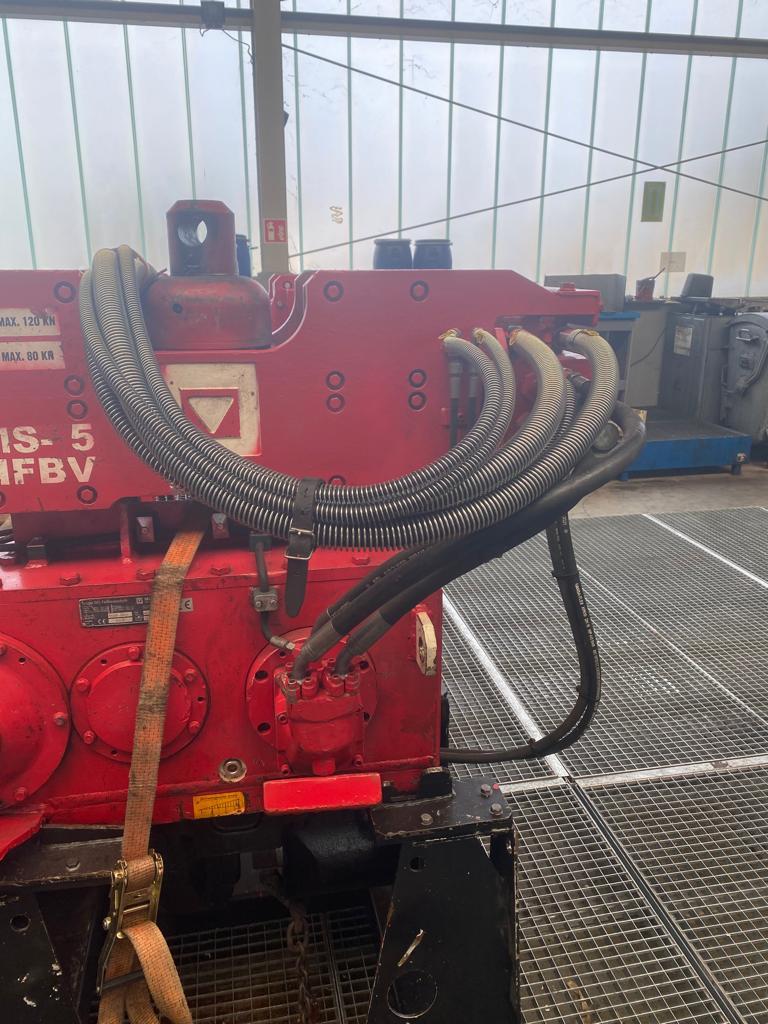

MÜLLER EXCAVATOR-MOUNTED VIBRATORY HAMMERS HFBV-SERIES.

The HFBV series offers maximum performance with minimum ground vibration. This makes them ideal for inner-city applications, special civil engineering projects or for work in vibration-sensitive environments.

HFBV-SERIE

APPLICATIONS

- Urban foundation works

- Areas sensitive to vibration

- Ideal for sandy soils

ADVANTAGES

- Minimal ground vibration

- Optimal adaptation to soil conditions

- Technology that’s easy on both the equipment and the environment

MÜLLER EXCAVATOR-MOUNTED VIBRATORY HAMMERS HFBV SGX-SERIES.

- COMPACT: WORK IN LIMITED INSTALLATION SPACES

- HIGH SAFETY STANDARD: RESONANCE_FREE START AND STOP

- MULTI-PURPOSE: PICKING UP, CLAMPING AND RAMMING IN A SINGLE OPERATION

With the launch of our new series MS-HFBV SGX, we are extending our established series of side-grip excavator-mounted vibratory hammers MS-HFB SG by variable machines with a resonance-free start and stop system. This means that e.g. sheet piles can be driven into the ground precisely, quickly and independently by the excavator operator, even in vibration-sensitive installation spaces. The new series makes it possible to grip the pile laterally from a lying position, to clamp it and to drive it into the ground in a single operation.

KEY DATA

- Performance categories*: MS-6, MS-8, MS-10 HFBV SGX

- Driving and extracting of sheet piles and beams

- Compatible with sidegrip-clamping device: MS-U 43 SG

- Tilt-rotating device: controllable through excavator joystick and switching foot pedal

- Vertical alignment via tilt sensor and indicator

- Clamping device can be mounted 90° rotated

*The number in the performance category stands for eccentric moment (kgm)

ADVANTAGES

- Easy setup through connection to the excavator's hydraulic system

- Adapter for all common quick-coupler systems

- Higher safety standard: no physical contact with the pile

- Zero resonance: minimal vibration propagation in the ground; minimizes wear-and-tear of your equipment

- Allows work in limited installation spaces

- Allows work with longer pile

MÜLLER EXCAVATOR-MOUNTED DRILL DRIVES RHA SERIES.

These robust, low-noise drill drives are quickly and easily attached to the stick of an excavator. Optionally, connection is possible through a guide carriage on a leader or by picking up the drill drive with the clamping device of the vibratory hammer.

RHA-SERIES.

APPLICATIONS

- Pre-drilling to loosen and relieve the ground

- Heavy soils

ADVANTAGES

- Various mounting options

- Fast, cost-effective drilling

- Powerful, robust, long life

MÜLLER SIDE-GRIP EXCAVATOR-MOUNTED VIBRATORY HAMMERS HFB SG-SERIES.

MÜLLER EXCAVATOR-MOUNTED VIBRATORY HAMMERS WITH SIDE GRIPPER

Our MÜLLER side grippers are capable of picking up, positioning, and driving a pile with the vibratory hammers in a single operation. This is a key advantage on space or height-restricted job sites especially, as conventional excavator-mounted vibratory hammers have to pick up the pile from the top.

ADVANTAGES

- With tilt-rotating device and lateral clamping device

- Ideal for applications with restricted space

- Outstanding maneuverability, supreme reliability, and very easy handling

- Lateral clamping device is mounted sturdily

- Can be mounted on almost any standard excavator without interfering with the hydraulics

- Vertical alignment via tilt sensor and indicator

- Made in Germany

MÜLLER EXCAVATOR-MOUNTED VIBRATORY HAMMERS WITH SIDE-GRIP CLAMPING DEVICE FOR PIPE PILES

Easy clamping of pipe piles: Only a few simple changes are necessary to replace the standard side-grip clamping device with the innovative side-grip clamping device for pipe piles, which enables tubular piles with a diameter of approx. 200 to 630 millimeters to be clamped. This unique design allows for defined application of force. Standardized MÜLLER MS-U 60/72 or MS-U 80/100 clamping devices can be supported without problems.

ADVANTAGES

- Standard side-grip clamping device can easily and quickly be replaced with side-grip clamping device for pipe piles

- Like all MÜLLER side grippers, this side gripper is also available in a one and two-cylinder design

reference projects

Machinery - MÜLLER Vibration Technology

EXTREMELY CRAMPED CONDITIONS WHEN PULLING BERLIN SHORING IN BERLIN-PANKOW

Read moredownloadcenter