Sustainable steels

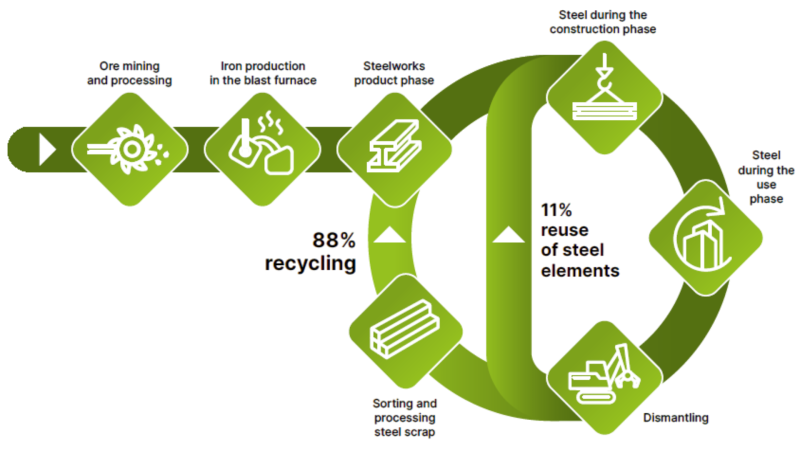

Steel is 100% recyclable without any loss of quality. The steel industry in Germany alone uses around 20 million tons of steel and iron scrap every year to manufacture new products. A well-functioning steel recycling system is already established in Germany. For example, the collection rate for structural steel at the end of its construction life is around 97%. All collected steel is sent for recycling.

The transformation to climate neutrality in the steel industry is taking place in stages, depending in part on the growing availability of green electricity and climate-neutral hydrogen. A classification system should be able to map this step-by-step transformation process and provide targeted incentives and support for the efforts and additional costs associated with the individual transformation steps. For this reason, the steel produced is divided into different categories of process ambitions and emission intensity.

The International Energy Agency (IEA) has proposed a six-stage classification system for this purpose. Based on this, the German Steel Association (supported by the Federal Ministry for Economic Affairs and Climate Protection) has founded the Low Emission Steel Standard (LESS) initiative, which aims to accelerate the development of demand for low-emission steel and enable initial sales markets. LESS is specifically designed to support the transformation of the steel industry through marking, which maps the step-by-step path to climate neutrality and allows for comparison between steel products manufactured using different processes.

The LESS system consists of several elements: Specifically, a classification scale in the labeling system illustrates whether the steel is “near-zero”2 or “low emission (A-D)”3. The thresholds used to classify the steel are based on the greenhouse gas intensity of the ton of hot-rolled steel produced and the specified scrap input. As part of a “sliding scale” – similar to the approach taken by the International Energy Agency – the limited global availability of steel scrap is taken into account, and the transformative efforts on the part of the primary and secondary steel routes are represented on a uniform scale.

Every construction site is different. That's why our output always begins with a consultation, during which we work with our customers to select the right material and machines for a tailor-made solution. The fact is, for every challenge,

we have more than one solution at our product range. This also applies to sustainability. With a wide range of products in our portfolio, we already meet the EU's emission reduction targets for 2030.

It is therefore worth comparing us with our competitors, from the manufacturing process at the material itself. With a wide range of products in our portfolio, we already meet the EU's emission reduction targets for 2030! Even without the use of green electricity, our steal beams score highly with a CO₂ value of 688 kg CO₂ e/t. Since 1996, our beams have been produced using low-emission electric arc furnaces with 100% scrap recycling.

The power supply for this comes from a residual electricity mix. There is no double counting of allocated renewable energy! For customers with an even stronger focus on their CO₂ footprint, we offer a green alternative: Beams with a CO₂ value of only 366 kg CO₂ e/t from the electric arc furnace route.

With 100% scrap recycling and green electricity from wind power directly from the producer. With this product range, you can already save 47% in CO₂ emissions today!